the mCmullen & wing yard

Our facilities are extensive and are brought to life by a skilled, cohesive team with all aspects of your project managed onsite including design, engineering & fabrication.

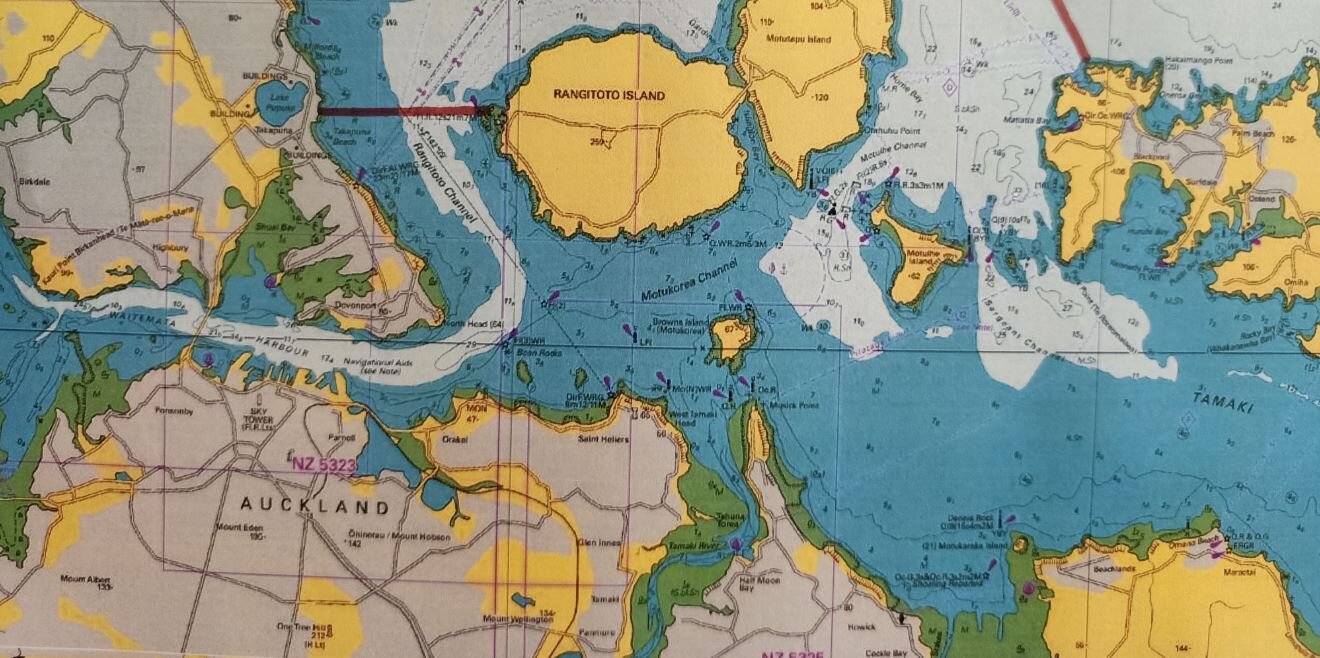

A deep water channel takes vessels down the Tamaki River and into the Waitemata Harbour.

CONSTRUCTION HALLS

With four separate construction buildings, plus full engineering and joinery workshops, design office and administration block, we have ample facilities to accommodate multiple projects. All of our main construction halls have overhead gantries and are accessible by our 65 tonne travelift, while larger new-build and refit projects make use of our main construction sheds or 300 tonne slipway.

Shed 1 is 57-metres long and 13-metres high with 2 x 3-tonne gantries.

Shed 2 is 45-metres long, 13-metres wide and 10-metres high and directly served by our slipway.

The build bay in Shed 3 is over 30-metres long, 10-metres wide and 9-metres high with a 5-tonne gantry.

Shed 3 also houses our CNC Plasma Cutter and 120-tonne hydraulic press brake.

Shed 4, added in 2024, is 60-metres long, 13-metres wide and 10-metres high, and sits adjacent to Shed 1.

300 TONNE SLIPWAY

300 tonne concrete slipway serving a stand-alone 45 metre shed.

Two slipway trolleys, able to haul vessels to 50 metres in length.

ONSITE TRAVELIFT

65 tonne capacity

6.8m beam

DEEP WATER WORK BERTHS

McMullen & Wing's work berths can accommodate vessels up to 50-metres in length and with over 4-metres draft, at all times.

ONSITE DESIGN AND ENGINEERING

Our full in-house engineering office staffed by an experienced, multi-disciplinary design team, enables maximum design flexibility and opportunity for stakeholder engagement throughout the build process.

Full CAD capabilities ensures detailed construction and systems information for both the construction period of the vessel, and also available for long term maintenance. Whenever scheduled maintenance is due, we'll have the vessel's information at our fingertips and ready to go.

PROJECT MANAGEMENT TEAMS

All projects are managed in-house with dedicated Project Managers in charge of all aspects of build construction and logistics.

QUALITY CRAFTSMEN ONSITE

Our certified welders work alongside highly-experienced metal workers and marine engineers, while our experienced boat-building staff specialise in both metal and composite fabrication.

Our world-class tradesmen mean all your work can be carried out onsite, with hand finishing, careful selection of materials and our team's inherent love of beautiful vessels elevating the finish you can expect on your yacht.

4x CONSTRUCTION SHEDS

SLIPWAY

TRAVELIFT

DEEP-WATER BERTHS

PLASMA CUTTER

BRAKE PRESS

CNC ROUTER

PROLINER MEASUREMENT

PROJECT MANAGEMENT

ONSITE DESIGN

SKILLED TRADESMEN